Troubleshooting Sudden Rotation Failure Without Action During Operation of a Truck-Mounted Crane

Troubleshooting Sudden Rotation Failure Without Action During Operation of a Truck-Mounted Crane

Fault Analysis

1. Incorrect electrical parameter settings;

2. Issues with joystick, controller, or switches;

3. Rotation brake cylinder not released;

4. Rotation pump producing no output;

5. Gearbox seized, motor experiencing severe internal leakage or seized;

6. Hydraulic lines incorrectly connected or depressurised.

Fault Management

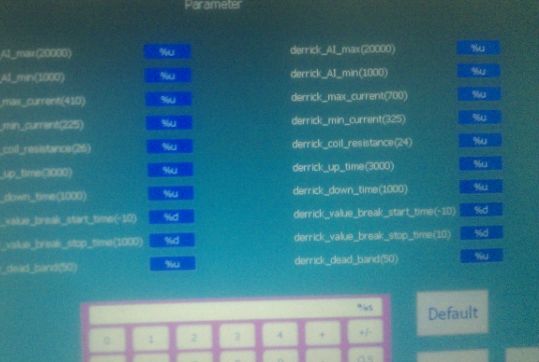

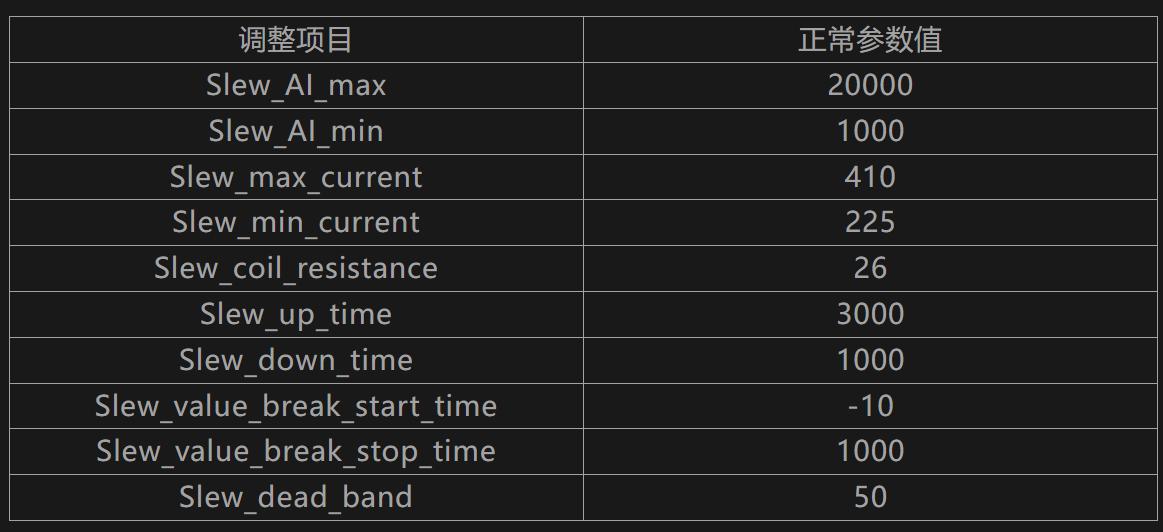

Enter the super password 1868 on the display to access the parameter adjustment interface (Figures 1 and 2). Navigate to the rotation page and verify that the parameters are correct (refer to the table below for standard parameter values). After completing parameter adjustments, proceed to the final page to save the settings. When navigating pages, advance one page at a time with deliberate movements to prevent data loss.

Operate the joysticks and switches while observing the corresponding values on the I/O monitoring page of the host display screen. If no change is observed, first inspect the wiring harness from the joystick to the 2023 controller for open circuits, loose connectors, or other faults. Should the wiring harness appear intact, the issue may lie with the joystick itself. To confirm this, swap the left and right joysticks to determine the cause.

If the display output and switches function correctly, the rotation direction of the operating handle remains unchanged. Using a multimeter, measure the rotation output voltage: Left rotation (432, 433) Right rotation (434, 435) Brake cylinder (436) The main pump output can be observed by monitoring its left and right rotation output pressure.

If the PLC outputs and wiring are fault-free, this indicates a problem with the oil pump. Further inspection is required to verify the integrity of the pump's inlet, drain, and outlet lines, ultimately determining the condition of the oil pump.

Inspect whether the gearbox gears or brake cylinder brake pads exhibit any sticking or jamming. Check whether the slewing motor is experiencing internal leakage or has seized. Remove the slewing motor from the gearbox and manually rotate it to observe whether it operates normally. If the motor functions correctly, the fault lies within the slewing gearbox. Proceed to dismantle the gearbox for further examination. (As shown in the diagram above)

Rotary motor internal leakage inspection: Remove the motor drain pipe and observe the leakage volume. Should a significant amount of hydraulic fluid spray outward, this indicates severe internal leakage in the rotary motor, necessitating its replacement.

Inspect the hydraulic pipe connections for any issues. As the rope-passing winch is connected in parallel with the slewing hydraulic circuit, internal leakage in the winch motor prevents pressure build-up in the slewing system, resulting in no slewing action.

Upon inspection, it was observed that during rotation, the hydraulic system pressure remained around 1MPa. Further examination revealed that the pressure was leaking from the rope winch motor connected in parallel to the slewing motor. After disconnecting the oil line connected to the rope winch, a test run was conducted, and normal operation was restored!

Recommendation

During hoisting operations, disconnect the A and B working hydraulic hoses from the rope-threading winch. Reattach them only when dismantling or assembling the vehicle to prevent prolonged pressure from causing leakage in the rope-threading winch motor and resulting in malfunction.

To assist more crane operators in managing their equipment effectively, we shall be launching additional case studies for truck-mounted cranes, crawler cranes, and truck-mounted derrick cranes in the near future. We encourage you to follow and share these updates. For further enquiries regarding repairs or spare parts, please contact us via WhatsApp at +86 175 7001 1677. Our 24-hour service remains at your disposal. Thank you for your continued support!